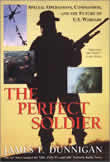

The Perfect Soldier: Special Operations, Commandos, and the Future of Us Warfare by James F. Dunnigan

More Books by James Dunnigan

|

Hornets Hurting

by James Dunnigan

August 13, 2008

Discussion Board on this DLS topic

The U.S. Navy has found that both their older F-18C Hornet fighters, and their newer F-18E "Super Hornet" are wearing out faster than expected. This was sort of expected with the F-18Cs, which entered service during the late 1970s and early 80s. These aircraft were expected to last about twenty years. But that was based on a peacetime tempo of operations, with about a hundred carrier landings (which is hard on the airframe) per year. There have been more than that because of the 1991 Gulf War (and the subsequent decade of patrolling the no-fly zone) and the war on terror. So to keep enough of these aircraft operational until the F-35 arrives to replace them in the next decade, new structural components (mainly the center barrel sections) are being manufactured. This is good news for foreign users of the F-18C, who want to keep their aircraft operational for longer.

The F-18E entered service about a decade ago, and was supposed to last 6,000 flight hours. But the portion of the wing that supports the pylons holding stuff (bombs, missiles, equipment pods or extra fuel tanks) is now expected to be good for no more than 3,000 flight hours. The metal, in effect, is weakening faster than expected. Such "metal fatigue", which ultimately results in the metal breaking, is normal for all aircraft. Calculating the life of such parts is still part art, as well as a lot of science. Again, unexpectedly high combat operations are the culprit. One specific reason for the problem was the larger than expected number of carrier landings carrying bombs. That's because so many missions flown over Iraq and Afghanistan did not require F-18Es to use their bombs or missiles.

The navy is modifying existing F-18Es to fix the problem, which is a normal response to such situations. Sometimes these fixes cost millions of dollars per aircraft, but this particular fatigue problem will cost a lot less to fix. The wing metal fatigue problem does not occur with the older F-18s (the A, C and D models) because, while they are also called F-18s, they are not the same as the F-18 E, F and G models. That's because, when the navy decided to build a replacement for the earlier F-18, they found they could get away with calling it an upgraded F-18 model. Thus, instead of it being called the F-24 (the next number available since the start of the Department of Defense's standard designation system in 1962) it could be called the F-18 E and F. While the F-18F looks like the original F-18, it is actually quite different. The F-18E is about 25 percent larger (and heavier) than the earlier F-18s, and had a new type of engine. By calling it an upgrade, it was easier for the navy to get the money from Congress. That's because, in the early 1990s, Congress was expecting a "peace dividend" from the end of the Cold War, and was slashing the defense budget. There was a lot of commonality between the two F-18s, but they are basically two different aircraft. Thus when used more heavily than expected, they developed metal fatigue in different parts of the airframe.

|

|